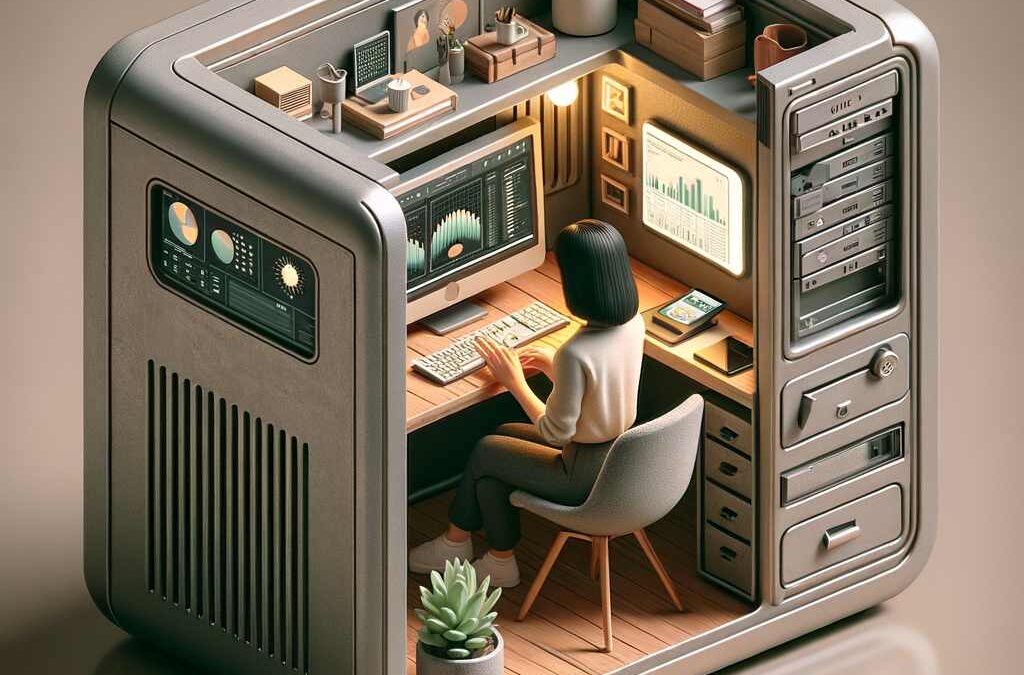

In today’s rapidly evolving business landscape, reactive approaches to equipment maintenance are becoming obsolete. Forward-thinking enterprises increasingly leverage analytics-driven predictive maintenance dashboards to gain early insights and proactively mitigate risks. With intelligently designed dashboards tracking real-time metrics, predicting wear and tear, and enabling proactive interventions, businesses avoid costly downtime and ensure operational excellence. Effective predictive maintenance is not merely a convenient bonus—it’s a critical competitive differentiator, translating directly into enhanced productivity, reduced operational expenditure, and increased reliability. Ready to harness technology-driven innovation for your maintenance needs? Let’s explore how predictive maintenance dashboards are becoming the cornerstone of modern equipment management strategies.

Understanding Predictive Maintenance and Its Importance

Before diving deep into the technological aspects, let’s clarify what predictive maintenance truly is. Unlike reactive maintenance, where interventions occur post-failure, or preventive maintenance, which follows fixed intervals regardless of actual equipment health, predictive maintenance leverages real-time and historical data analytics to foresee equipment failure accurately. By harnessing advanced machine learning algorithms and data-driven insights, predictive maintenance proactively identifies anomalies, minimizing unplanned downtime and enhancing efficiency.

The importance of predictive maintenance dashboards is unparalleled in high-stakes industries such as manufacturing, logistics, energy production, and healthcare. Imagine a manufacturing facility where a critical component fails unexpectedly, causing prolonged downtime, delayed deliveries, and potentially significant financial losses. Now visualize a dashboard capable of monitoring equipment health ubiquitously, alerting personnel days or even weeks before potential failures, allowing ample time for corrective action. Reliably predicting issues reduces emergency repairs and associated overtime costs, extends asset life, and helps organizations shift from reactive damage control into strategic forward planning. Businesses across sectors value these technological solutions to proactively improve bottom-line efficiency and safety. For even deeper context, explore strategic data insights in our article on use cases for data-driven businesses.

How Predictive Maintenance Dashboards Harness the Power of Data

A well-functioning predictive dashboard collects enormous amounts of data from various equipment sensors and operational monitoring systems embedded throughout a facility. This robust gathering of structured and unstructured data includes sensor readings such as temperature, vibration frequencies, pressure conditions, runtime hours, energy consumption, and historical maintenance logs. Such comprehensive data acquisition can benefit immensely from professional Advanced ETL Consulting Services, ensuring efficient predictive modeling and data readiness.

Once collected, intelligent algorithms process data streams in real-time or near-real-time conditions. With the continual evolutionary improvements in data analytics and IoT (Internet of Things), businesses can now perform powerful analyses combining structured and unstructured data efficiently. In practice, machine learning techniques like supervised learning or neural networks examine past historical patterns and current sensor feedback to identify actionable trends. For instance, vibration deviations exceeding normal operational range thresholds may indicate mechanical deterioration. By validating anomalies with previous maintenance instances, the dashboards effectively anticipate specific failures, supporting timely preventative interventions.

To enhance the effectiveness and clarity of dashboard visualizations, businesses often employ sophisticated visual techniques like self-explaining visualizations with embedded context, allowing everyone—from seasoned engineers to non-technical business stakeholders—to interpret the predictive dashboard effortlessly.

Key Components of Effective Predictive Maintenance Dashboards

Designing predictive maintenance dashboards isn’t just about data availability—they require careful strategizing around specific components for maximum impact. Key dashboard elements include real-time metrics on equipment health, specific fault detection modules, predictive algorithms, and alert systems designed around business operational workflows. Furthermore, efficient dashboard designs embrace clarity, ease of operation, and intuitive interfaces to make rapid interpretation seamless across organizational teams.

Additionally, predictive dashboards greatly benefit from thoughtful integration with established data engineering best practices. Having a thoroughly prepared and clean data pipeline is foundational. Companies increasingly leverage effective data documentation strategies and robust data enrichment pipeline architecture patterns, ensuring the dashboards’ underlying systems remain coherent, maintainable, and transparent.

An optimal dashboard should also provide predictive modeling insight clearly and communicate anomaly metrics effectively through visualization techniques. Integrating feature-rich visualizations, such as custom event visualizations (explore our guide on event droplines for temporal sequence visualization) and comparative analyses through advanced visual representations like network visualization layout algorithms, allows maintenance teams to spot and address critical performance bottlenecks immediately.

Infrastructure and Data Strategy for Effective Dashboard Deployment

The effectiveness of a predictive dashboard largely depends on supporting infrastructure. Reliable data integration, scalable cloud or on-premise systems, and flexible analytic tools underpin dashboard performance. Leveraging Infrastructure as Code (IaC) methodologies ensures scalability, consistency, and faster iteration cycles. IaC enables businesses to define and manage their analytics infrastructure declaratively, enhancing data pipeline reliability and agility critical for predictive maintenance initiatives.

Additionally, choosing a resilient and scalable architecture allows for streamlined data integration from diverse IoT sensor networks into the predictive dashboard effortlessly. Leveraging file systems like Hadoop or analytical engines like Apache Spark, combined with data warehousing solutions, can seamlessly integrate data from varied sensors and sources into unified dashboards capable of insightful predictive analytics. Strategies detailed in our beginner’s guide to data modeling for analytics prove particularly valuable in preparing your data systems effectively.

Optimizing metadata collection is also a pivotal aspect of data strategy. Implementing tools such as Colibri Tableau dashboards for improved server metadata collection supports advanced auditing capabilities and better system governance, important for maintaining analytics infrastructure health amidst a rapidly growing data environment.

Real-world Applications: Predictive Maintenance Dashboards in Action

Predictive maintenance dashboards continue driving significant impact across industries with considerable success. For example, the energy sector uses predictive analytics dashboards for power generation equipment, detecting performance degradation and preempting costly failures in turbines and transformers. Similarly, transportation and logistics companies effectively use predictive models to monitor vehicle performance, ensuring seamless logistical operations by preventing unscheduled break-downs or maintenance lapses.

In manufacturing sectors, critical equipment like conveyor belts, motors, compressors, and pumps regularly benefit from real-time monitoring dashboards. A predictive approach guides businesses toward preventive interventions, identifying and addressing potential failures early and ensuring uninterrupted factory floor productivity. The healthcare and medical sectors increasingly employ predictive maintenance dashboards to maintain hospital equipment reliability, ensuring patient safety by preventing unexpected downtime in critical care environments.

Interested in learning more about the transformative potential of predictive dashboards powered by IoT innovations? Our detailed overview “Unlocking the Power of IoT: How Connected Devices Are Driving Business Innovation” provides invaluable insights into data-driven enterprise innovations.

The Competitive Advantage of Predictive Maintenance Dashboards

Companies embracing data analytics and predictive dashboards noticeably differentiate themselves by operating with increased reliability, significantly reduced operational costs, and greater equipment longevity. Predictive dashboards allow for smarter resource allocation, fewer interruptions, improved equipment efficiencies, optimized inventory and spare parts management, and enhanced customer satisfaction.

By reducing downtime, your organization establishes a reputation for reliability—crucially beneficial in highly competitive market landscapes. Predictive maintenance dashboards foster innovation, empower operational agility, and form the foundational stepping stones towards digitally transformative practices, setting you far ahead of conventional, reactive business competitors.

Conclusion: Embracing Dashboard Innovation for Preventive Excellence

As we’ve seen clearly throughout this journey, predictive maintenance dashboards deliver undeniable strategic value. Their successful deployment depends upon robust data integration, intelligent analytics, and thoughtful visualizations integrated into your business operations. The competitive edge provided by predictive analytics dashboards translates directly into quantifiable efficiency, profitability, and improved reliability. Your strategic investment in predictive dashboards becomes even stronger when supported by professional analytics implementation expertise. Isn’t it time your organization leveraged these powerful data-driven tools for optimal reliability and improved bottom-line performance?

Tags: predictive maintenance dashboards, data analytics, IoT innovations, equipment reliability, infrastructure strategy, advanced visualization

Thank you for your support, follow DEV3LOPCOM, LLC on LinkedIn and YouTube.