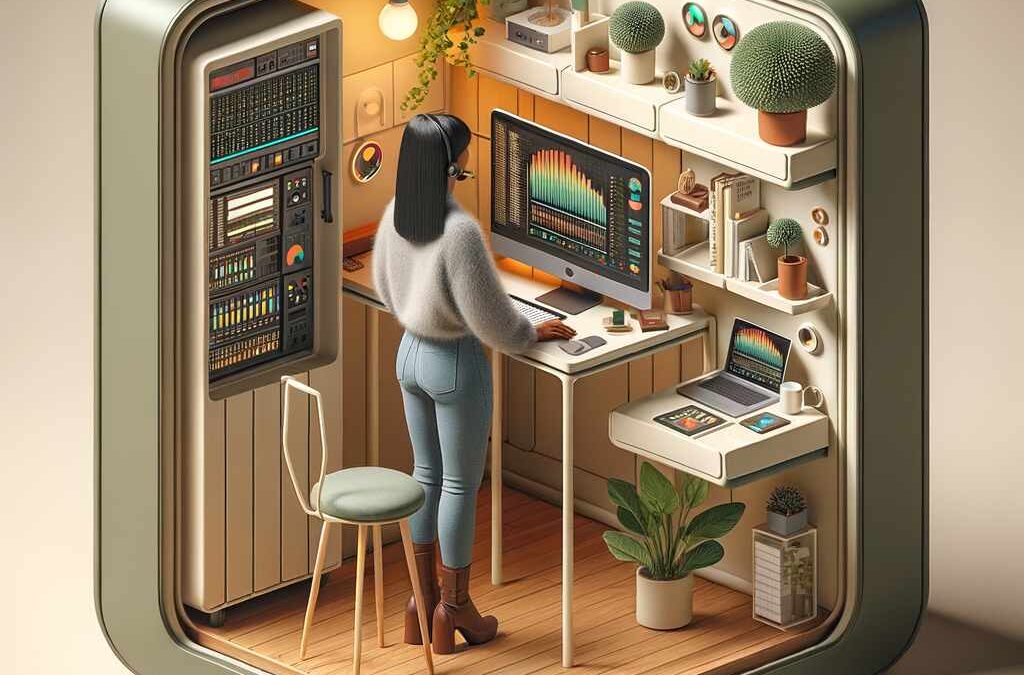

Imagine having unhindered visibility into your production line—knowing precisely what causes defects, forecasting issues proactively, and gaining control that turns insights into immediate improvements. In today’s hyper-competitive manufacturing environment, leveraging data-driven solutions like Statistical Process Control (SPC) Dashboards is no longer optional; it’s an essential strategy for quality-centric innovation. SPC dashboards combine analytics, visualization capabilities, and real-time insights to ensure manufactured items maintain highest standards, reduce waste, and generate optimal ROI. Leaders empowered with effective dashboards are better equipped to maintain streamlined operations, improve decision-making speed, and sustain an unyielding competitive edge. Let’s dive deeper into how Statistical Process Control Dashboards can revolutionize your manufacturing quality control strategy.

Strategic Importance of Statistical Process Control Dashboards in Manufacturing

In today’s competitive, data-driven manufacturing environment, leveraging Statistical Process Control Dashboards can spell the difference between market leadership and trailing behind competitors. SPC dashboards represent an innovative approach that harnesses powerful analytics and visualization tools to reveal insights in production processes previously hidden behind numbers and manual investigation. These dashboards offer decision-makers real-time insights, proactively pinpointing potential defects, verifying process stability, and identifying root causes of production anomalies. Such a proactive strategy significantly reduces downtime, defective products, and resource waste.

With products becoming increasingly complex and consumer expectations climbing higher than ever before, integrating comprehensive analytics dashboards becomes crucial. SPC dashboards provide transparency into manufacturing KPIs and enable manufacturing teams to consistently monitor process capability indices, measure process variability, establish data-driven control limits, and drive continuous improvement initiatives. Unlike manual quality control, which tends toward reactionary measures—addressing defects post-production—SPC dashboards enable predictive capability, alerting teams before a problem becomes costly.

The transition toward automated, analytics-focused quality control isn’t limited to operational efficiency alone. Deploying intelligent SPC dashboards also enhances strategic leadership by providing visibility into performance metrics with executive-level clarity. This empowers leadership with quantifiable intelligence, leading to informed decisions, improved product consistency, and reputational confidence—crucial components for success.

The Core Principles of Statistical Process Control (SPC)

Statistical Process Control involves the use of statistical methods to monitor and control production processes. SPC is underpinned by several foundational principles that focus on improving quality, increasing efficiency, and minimizing production risks. At its heart, SPC emphasizes detecting variability within production processes—special-cause variations (irregularities) and common-cause variations (expected variation). Understanding this distinction enables manufacturers to act promptly where necessary without unnecessarily overreacting and interfering with normally functioning workflows.

The primary tool in SPC is the control chart, a statistical visualization designed to signal abnormal process deviations promptly. Control charts display real-time data with upper and lower control limits calculated from historical process performance data. Whenever a data point breaches these predetermined control limits, quality engineers are alerted quickly, prompting immediate investigation and corrective action. SPC methodologies thereby deliver valuable insights that foster intelligent decision-making, reduce guesswork, and improve process reliability.

Another key principle underpinning SPC is continuous improvement. It’s not enough to merely track quality metrics; SPC encourages using accumulated information and insights to drive sustainable and meaningful enhancements over time. This aligns perfectly with creatively designed Dashboard visualizations, which make data easily comprehensible and actionable, supporting real-time adjustments and improvements in the field.

Harnessing Real-Time Insight: Creating Statistical Process Control Dashboards

The primary strength of SPC dashboards lies in their ability to offer manufacturers real-time feedback and predictive insights into complex manufacturing processes. Real-time analytics dashboards can collate data from disparate sources throughout the production line, enabling swift identification and diagnosis of issues before they transform into severe operational interruptions. Such an intelligent, timely approach to quality management allows decision-makers to mitigate risk strategically and productively.

Quality-focused teams that leverage advanced dashboard technologies can integrate innovative solutions such as real-time input validation strategies to maintain data accuracy across continuously streaming production data. Furthermore, companies dealing with data arriving asynchronously or delayed can implement advanced analytical techniques to efficiently handle and interpret these challenges—as explored in our guide on processing temporal data and late-arriving events.

With dashboards built on robust data engineering foundations—such as those we provide through our specialized data engineering consulting services—businesses can derive meaningful conclusions directly from their operational data. The intuitive and dynamic visualization capabilities enable anyone in the leadership or engineering teams to quickly grasp significant trends or anomalies, breaking free from complex spreadsheets and cumbersome manual analysis.

Implementing Your SPC Dashboard: Best Practices and Pitfalls to Avoid

Successful implementation of SPC dashboards is not merely about selecting a software tool; it involves aligning methodology, technology platform, data readiness, and internal organizational practices. Businesses must carefully construct a thoughtful plan integrating their SPC dashboard into quality processes, ensuring stakeholder involvement, proper training, and enabling seamless integration into daily workflows.

Companies may face challenges in effective implementation if operating on legacy data systems or outdated technological infrastructure. In such scenarios, organizations can establish clear and progressive transformation strategies by implementing a well-defined deprecation policy for legacy data assets. Addressing these challenges explicitly will permit smoother adoption of advanced analytics systems and alleviate resistance to newer innovations.

Potential pitfalls in dashboard implementation often involve data governance issues, insufficient stakeholder training, or inadequate documentation. Organizations that do not provide self-service reporting capabilities frequently find their data teams overwhelmed. Hence, investing resources into building robust self-service analytics platforms allows broader accessibility, decreased analyst dependence, and fosters a culture of agile decision-making throughout your manufacturing teams.

Long-term Benefits and Competitive Advantage SPC Dashboards Provide

Effective SPC dashboards provide an unmatched long-term competitive advantage through enhanced manufacturing efficiency, lower operational risk, and consistent product quality. By aggregating structured, timely data monitoring, these dashboards offer a solid foundation that helps manufacturing executives better understand performance drivers, thereby enabling informed decision-making and strategic cost controls.

Data-savvy executives capable of leveraging advanced analytics tools ensure operational decisions remain impactful and proactive. Gaining insights like defect probability, predictive maintenance requirements, or potential bottlenecks fundamentally transforms decision-making dynamics within your business. Understanding these critical concepts is covered extensively in our resource 20 tips executives need to understand about data warehousing.

Additionally, effective SPC dashboards drive organizational agility in responding promptly to changing customer expectations or emergent competitive threats. Timely, accurate data injections allow organizations to pivot quickly, ensuring continuous alignment with evolving industry trends and increasing customer satisfaction. Ultimately, this critical capability positions businesses ahead of rivals who still rely on outdated, manual methods.

Looking Ahead: Future Trends in Statistical Process Control Dashboards

Modern SPC dashboards build a foundation for growth, innovation, and technological progression within manufacturing environments. Looking toward the future, the evolution of SPC technology will increasingly rely on sophisticated predictive analytics, artificial intelligence, and machine learning techniques. These advanced capabilities will further streamline quality management, proactively solving issues before they emerge from massive historical process data collections.

Incorporating Internet of Things (IoT) devices, sensor networks, and real-time automated scanning and inspection data will add scalability and complexity to future dashboard iterations. Moreover, moving toward advanced cloud analytics, SPC dashboards will empower scalable, secure, multi-site deployments, driving innovative data-sharing capabilities and efficient cross-organizational collaboration.

Manufacturers aspiring toward operational excellence must stay ahead of these emerging trends, embracing new methods and strategies proactively. Solutions like SPC dashboards demonstrate the profound impact that data-driven innovations continue bringing to manufacturing success, reinforcing competitive dominance and fueling further technological discovery.

If your organization is looking to strategically execute data-driven manufacturing improvements, our expert team at Dev3lop provides comprehensive support that aligns your quality goals with effective analytics implementations. Embrace the innovation, efficiency, and competitive edge that SPC dashboards offer, equipping your manufacturing teams to thrive in an increasingly complex industry landscape.

Thank you for your support, follow DEV3LOPCOM, LLC on LinkedIn and YouTube.